| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 5 : | Ligne 5 : | ||

|Categories=Maintenance | |Categories=Maintenance | ||

|Difficulty=Easy | |Difficulty=Easy | ||

| − | |Duration= | + | |Duration=20 |

|Duration-type=minute(s) | |Duration-type=minute(s) | ||

|Tags=Laser Sensor, ZX4, ZX5, Flowline, Commissioning | |Tags=Laser Sensor, ZX4, ZX5, Flowline, Commissioning | ||

Version actuelle datée du 4 octobre 2019 à 09:58

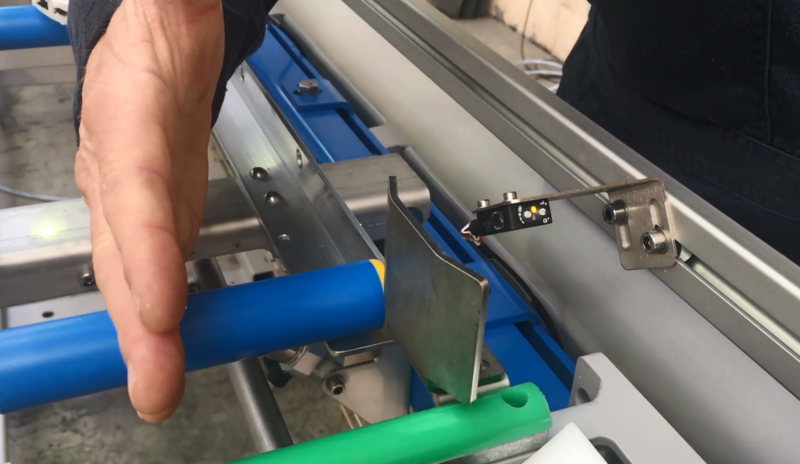

Setting up the laser sensors on the infeed of a Flowline, ZX4 and ZX5.

Introduction

Vimeo

Étape 1 - Adjust the "Light Dark"

Adjust the "Light Dark" balance on the sensor. To do this, using a small flat head screwdriver, turn the light dark dial clockwise until the orange light goes off. Then slowly turn anti-clockwise until the orange light turns on again, when this happens re-turn a little clockwise to turn off the orange light.

Étape 2 - Adjust Sensitivity

Now adjust the sensitivity. Place an object 80mm away from the sensor. Now adjust the sensitivity until the orange light turns on.

Étape 4 - Input Laser Measurements

From the 0 Position, measure the distance of each sensor. These should be written down on the sensors.

In the measurements settings (winMulti> Settings > measurements) update each offcutSensorX parameter with the exact measurements recorded.

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português