| [version en cours de rédaction] | [version en cours de rédaction] |

| Ligne 15 : | Ligne 15 : | ||

{{EPI}} | {{EPI}} | ||

{{Tuto Step | {{Tuto Step | ||

| − | |Step_Title=<translate>Infeed Vertical and horizontal rollers</translate> | + | |Step_Title=<translate>Infeed Clamp Vertical and horizontal rollers</translate> |

|Step_Content=<translate>Daily – remove any tape or debris which may have become entangled in the rollers | |Step_Content=<translate>Daily – remove any tape or debris which may have become entangled in the rollers | ||

| Ligne 52 : | Ligne 52 : | ||

|Step_Picture_00=Autoflow_Maintenance_-_Infeed_image15.jpeg | |Step_Picture_00=Autoflow_Maintenance_-_Infeed_image15.jpeg | ||

|Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":983,"height":1310,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.61,"scaleY":0.61,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/6/61/Autoflow_Maintenance_-_Infeed_image15.jpeg","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":412.5,"top":194,"width":83,"height":142,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":41.5,"x2":-41.5,"y1":-71,"y2":71,"x2a":-24.500762137627266,"y2a":57.770264095664146,"x2b":-38.31416286127206,"y2b":49.69623409522387},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":454,"top":123,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":371,"top":265,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":800,"width":600} | |Step_Picture_00_annotation={"version":"2.4.6","objects":[{"type":"image","version":"2.4.6","originX":"left","originY":"top","left":0,"top":0,"width":983,"height":1310,"fill":"rgb(0,0,0)","stroke":null,"strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":0.61,"scaleY":0.61,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"crossOrigin":"","cropX":0,"cropY":0,"src":"https://stuga.dokit.app/images/6/61/Autoflow_Maintenance_-_Infeed_image15.jpeg","filters":[]},{"type":"wfarrow2line","version":"2.4.6","originX":"center","originY":"center","left":412.5,"top":194,"width":83,"height":142,"fill":"rgba(255,0,0,0)","stroke":"#FF0000","strokeWidth":4,"strokeDashArray":null,"strokeLineCap":"round","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":1,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"x1":41.5,"x2":-41.5,"y1":-71,"y2":71,"x2a":-24.500762137627266,"y2a":57.770264095664146,"x2b":-38.31416286127206,"y2b":49.69623409522387},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":454,"top":123,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586},{"type":"wfarrow2circle","version":"2.4.6","originX":"center","originY":"center","left":371,"top":265,"width":16,"height":16,"fill":"#aaa","stroke":"#666","strokeWidth":0,"strokeDashArray":null,"strokeLineCap":"butt","strokeDashOffset":0,"strokeLineJoin":"miter","strokeMiterLimit":4,"scaleX":1,"scaleY":1,"angle":0,"flipX":false,"flipY":false,"opacity":0.5,"shadow":null,"visible":true,"clipTo":null,"backgroundColor":"","fillRule":"nonzero","paintFirst":"fill","globalCompositeOperation":"source-over","transformMatrix":null,"skewX":0,"skewY":0,"radius":8,"startAngle":0,"endAngle":6.283185307179586}],"height":800,"width":600} | ||

| + | }} | ||

| + | {{Tuto Step | ||

| + | |Step_Title=<translate>Outfeed Clamp Vertical and Horizontal Rollers</translate> | ||

| + | |Step_Content=<translate>Daily – remove any tape or debris which may have become entangled in the rollers | ||

| + | |||

| + | Weekly – apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings</translate> | ||

}} | }} | ||

{{Tuto Step | {{Tuto Step | ||

Version du 23 janvier 2020 à 14:27

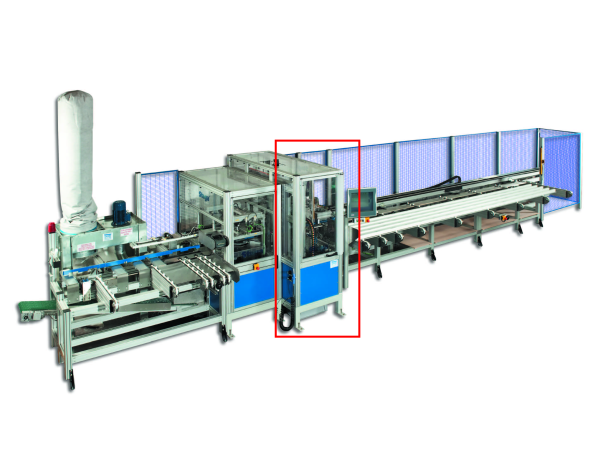

Procedures for Maintenance of the Autoflow Machining Centre Module

Sommaire

- 1 Introduction

- 2 Étape 1 - Infeed Clamp Vertical and horizontal rollers

- 3 Étape 2 - Spindle Motors

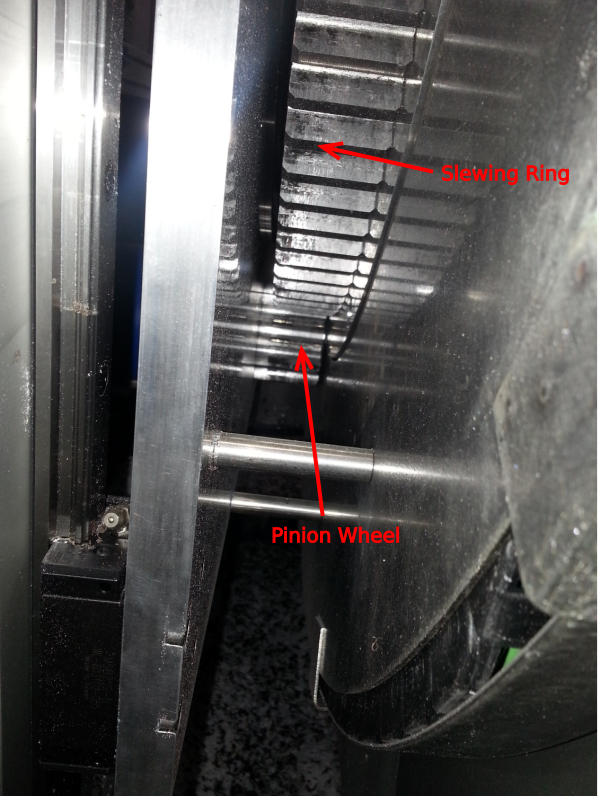

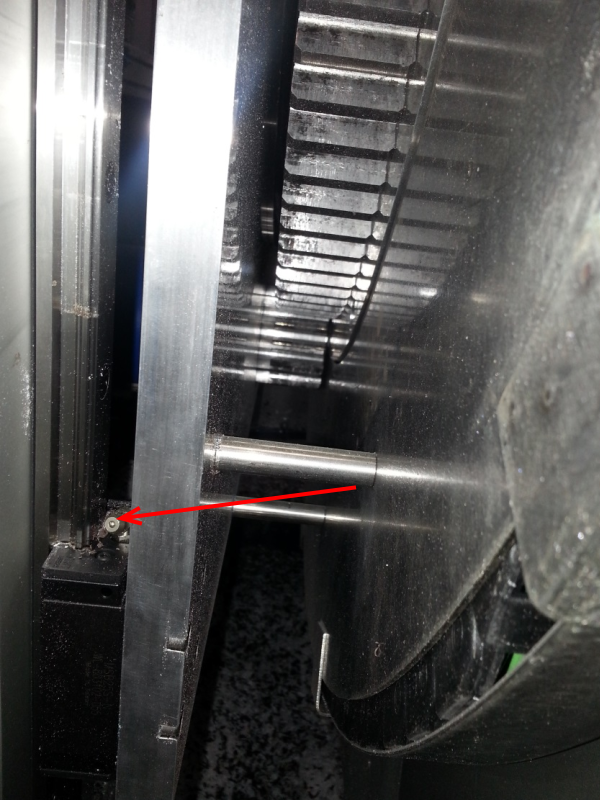

- 4 Étape 3 - Slewing Ring and Pinion wheel

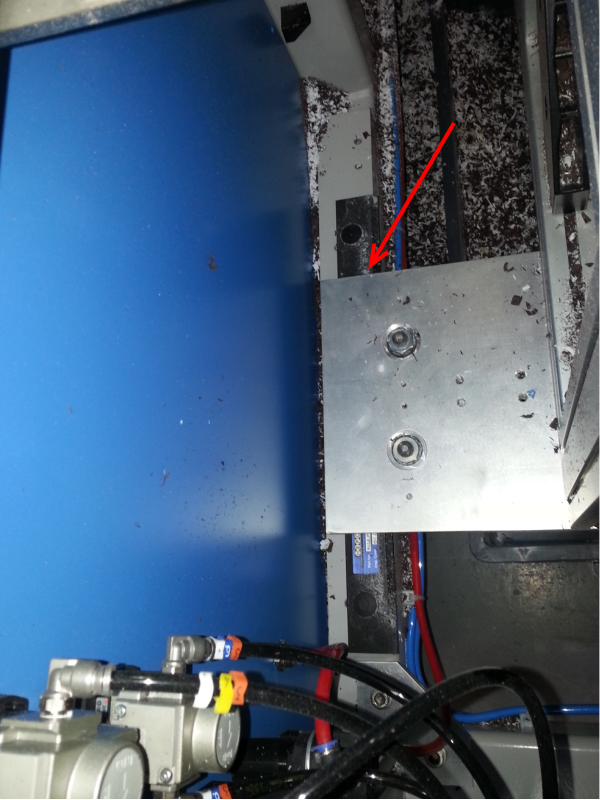

- 5 Étape 4 - Y Axis Rails

- 6 Étape 5 - Outfeed Clamp Vertical and Horizontal Rollers

- 7 Étape 6 - Z Axis Linear Bearings

- 8 Étape 7 - Auto lube System

- 9 Commentaires

Introduction

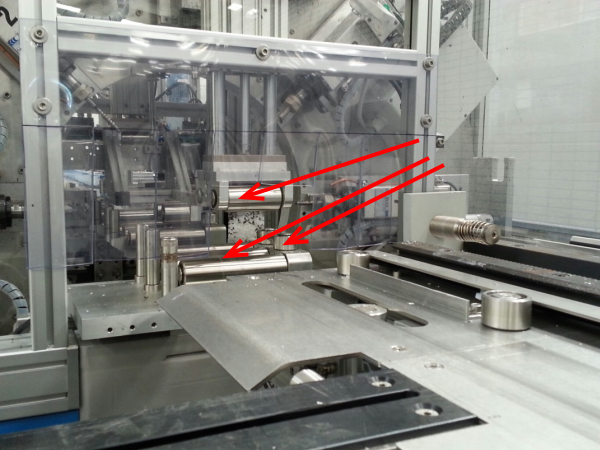

Étape 1 - Infeed Clamp Vertical and horizontal rollers

Daily – remove any tape or debris which may have become entangled in the rollers

Weekly – apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

Étape 2 - Spindle Motors

Daily – Ensure that each spindle will turn freely with no grinding noise when rotating, check cutters for chips or damage, check V – Notch blades for chipped or damaged teeth

Check Spindles slide freely in and out on full range of movement

Monthly - Lubricate slideway bearings

Étape 3 - Slewing Ring and Pinion wheel

Daily – clean area of swarf or debris

Weekly – visually check pinion wheel and slewing ring for any damage, chips or cracks, remove any debris that may have become caught up in the teeth

Étape 4 - Y Axis Rails

4 off Located at the bottom of the machining centre cabinet.

Daily – clean away any debris

Monthly– lightly oil rail surface with supplied oil

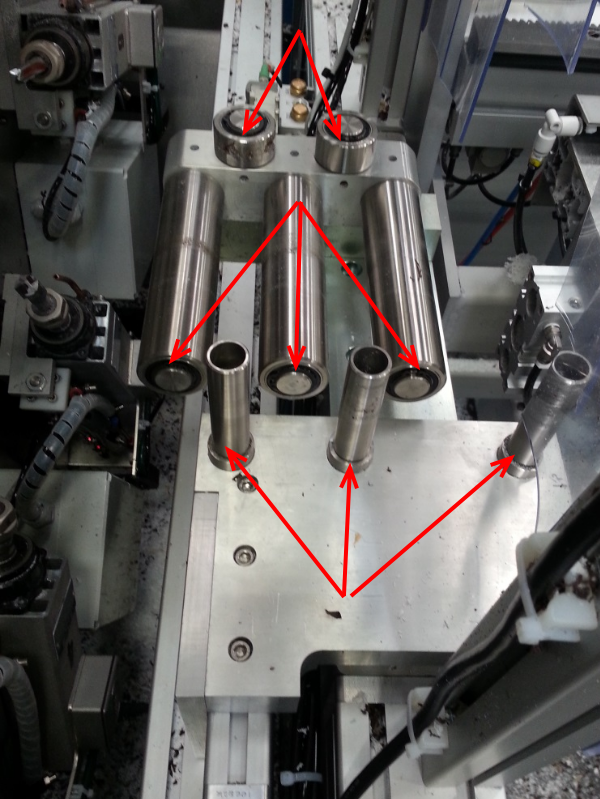

Étape 5 - Outfeed Clamp Vertical and Horizontal Rollers

Daily – remove any tape or debris which may have become entangled in the rollers

Weekly – apply oil to top and side of roller units and then slowly spin them for a few revolutions to allow the oil to penetrate the bearings

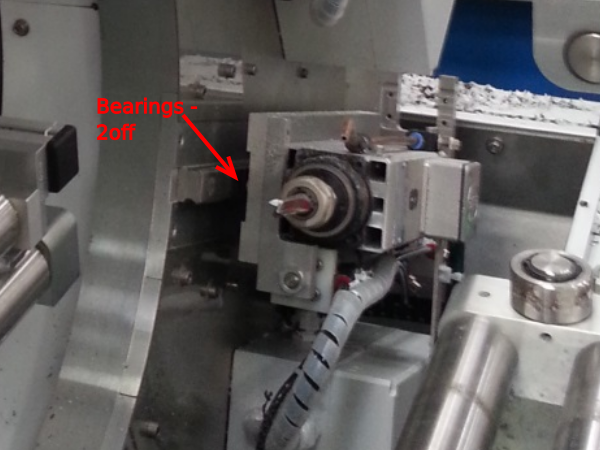

Étape 6 - Z Axis Linear Bearings

4 off

Daily – clear area of debris

Monthly– 1 – 2 pumps of grease via grease nipple, wipe away any excess grease

Étape 7 - Auto lube System

Check level of grease in Auto lube

Part replacement order code is M0001047

Draft

Français

Français English

English Deutsch

Deutsch Español

Español Italiano

Italiano Português

Português